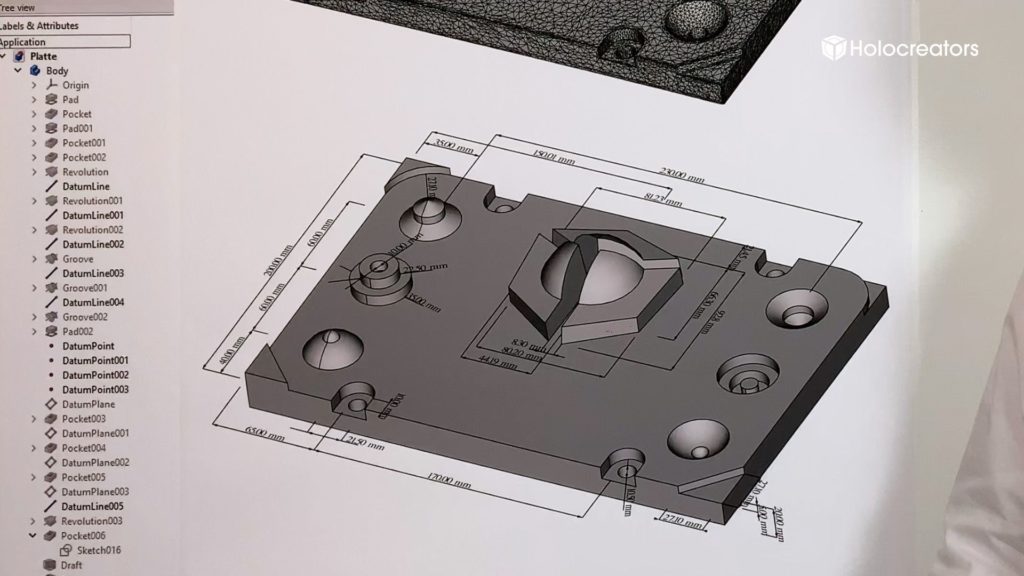

Reverse engineering to parametric modeling with a history tree involves converting a 3D scan into your native CAD format. The finished CAD model thus contains a history tree, and you can adjust all parameters yourself in your own CAD program. A technical drawing can be derived from the parametric CAD model with little effort.

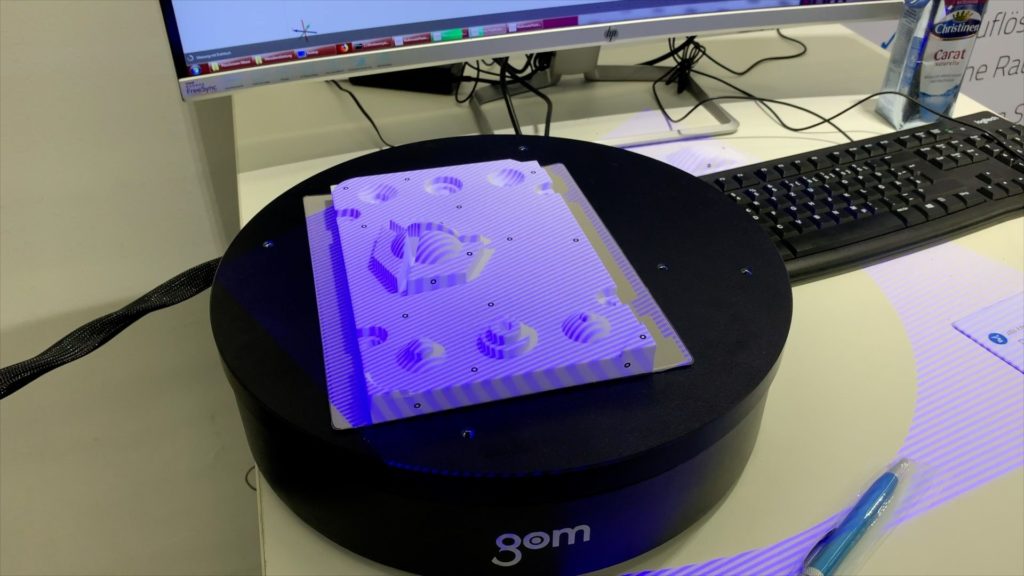

For reverse engineering to parametric model with a history tree, the 3D scan data should be available in a STL format or a point cloud format. Both are standard formats for 3D scans. If a 3D scan is not yet available, we at Holocreators will be happy to 3D scan your parts.

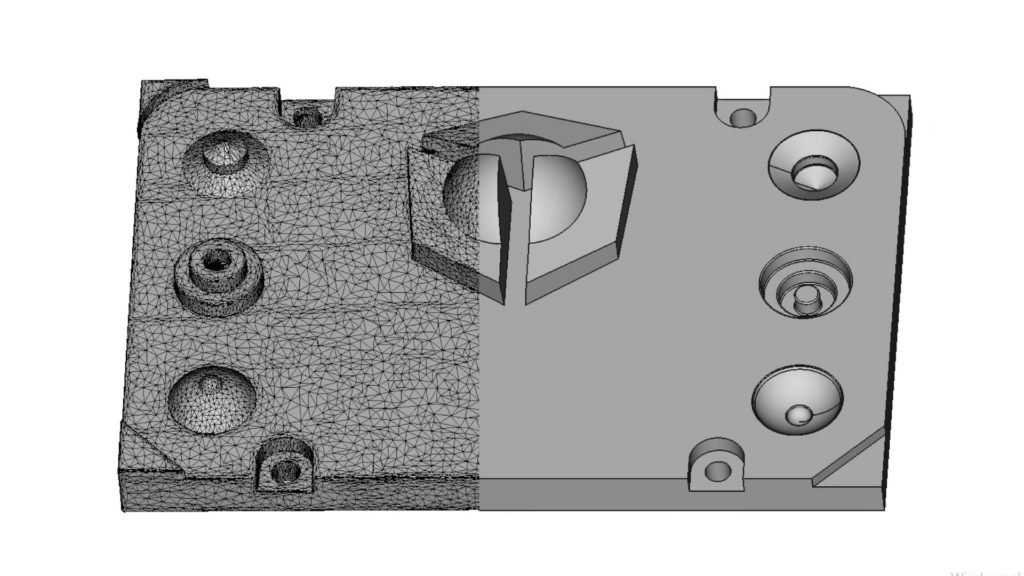

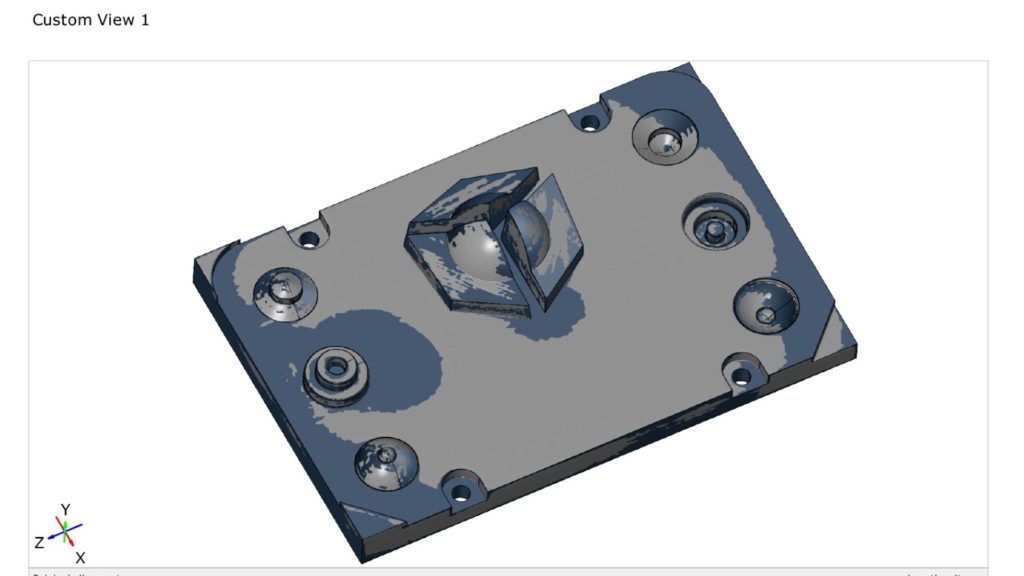

Reverse engineering to parametric modeling is based on reverse engineering to solid model. In the first step, the 3D scan is converted as accurately as possible into a solid model. Based on this solid model, the parametric model with a history tree is then generated in the same CAD software that the you use. All geometric elements are adapted according to industry standards.

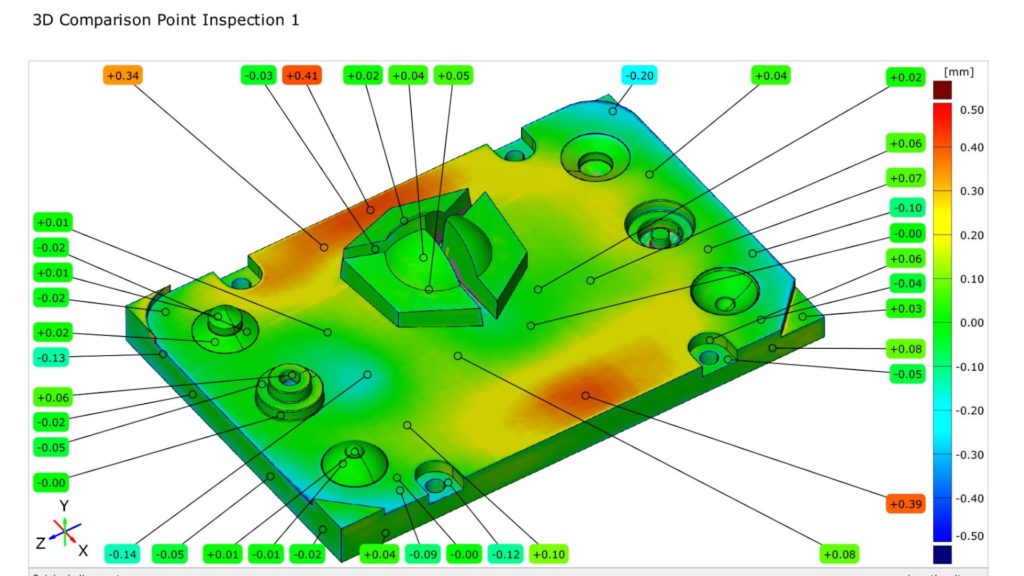

Reverse engineering to parametric model with a history tree is accurate. On average there are deviations of 0.05 mm to 0.25 mm between the original 3D scan and the generated parametric model. The amount of deviation is influenced by the degree of desired geometry optimization.

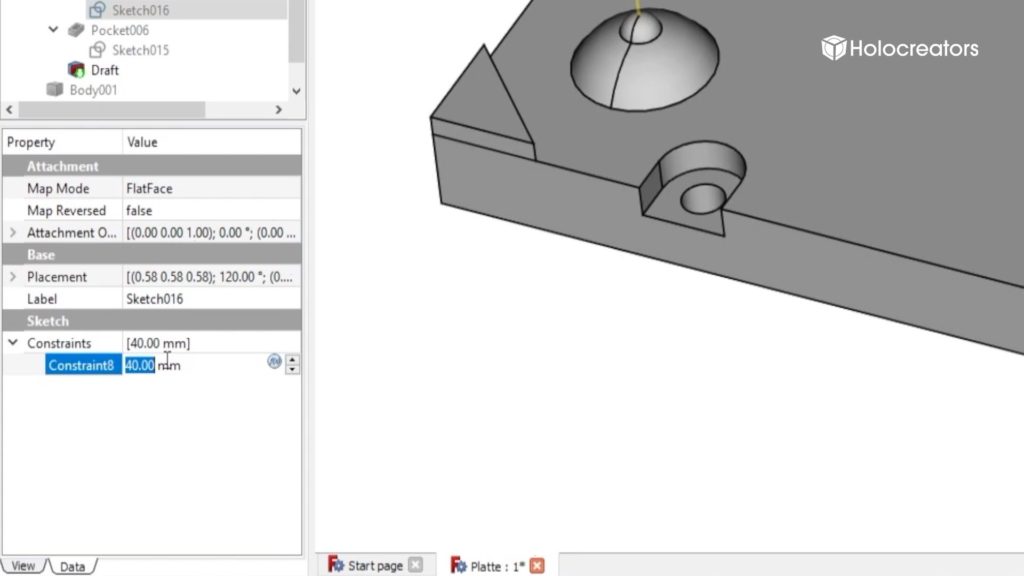

After Reverse engineering to parametric modeling with a history tree, the data is provided in your native CAD format. For example, say you work with the CAD software “FreeCAD.” The data would be exported in the native data format of FreeCAD, which is FCstd.

Holocreators offers this service for every CAD program that exists on the market. It is important that we agree with the customer in advance on the correct version number of the CAD software so that the finished data can be provided perfectly formatted.

With every reverse engineering to parametric model with a history tree, we create a deviation analysis. With this report, you can easily see how far the parametric model deviates from the original 3D scan.