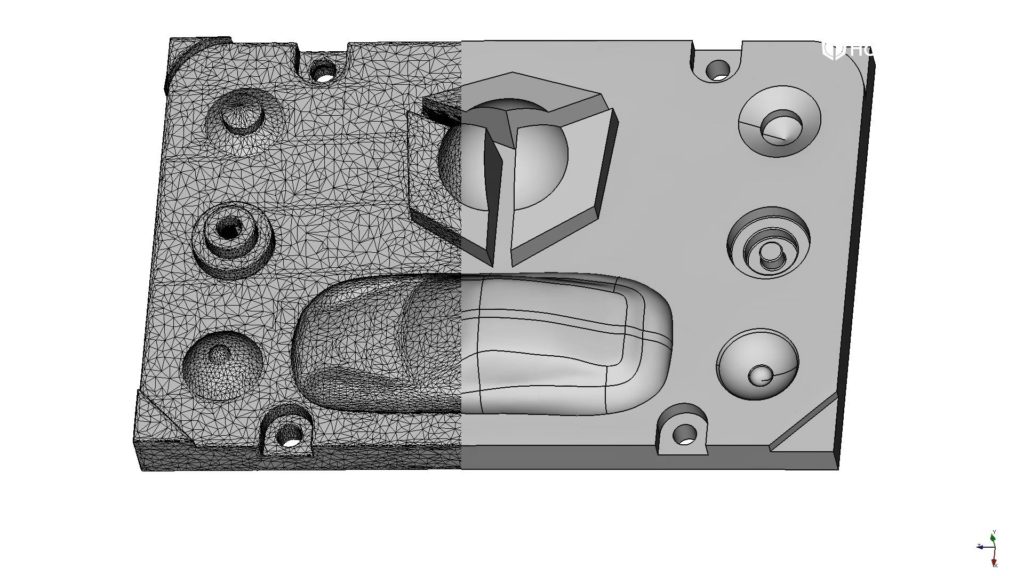

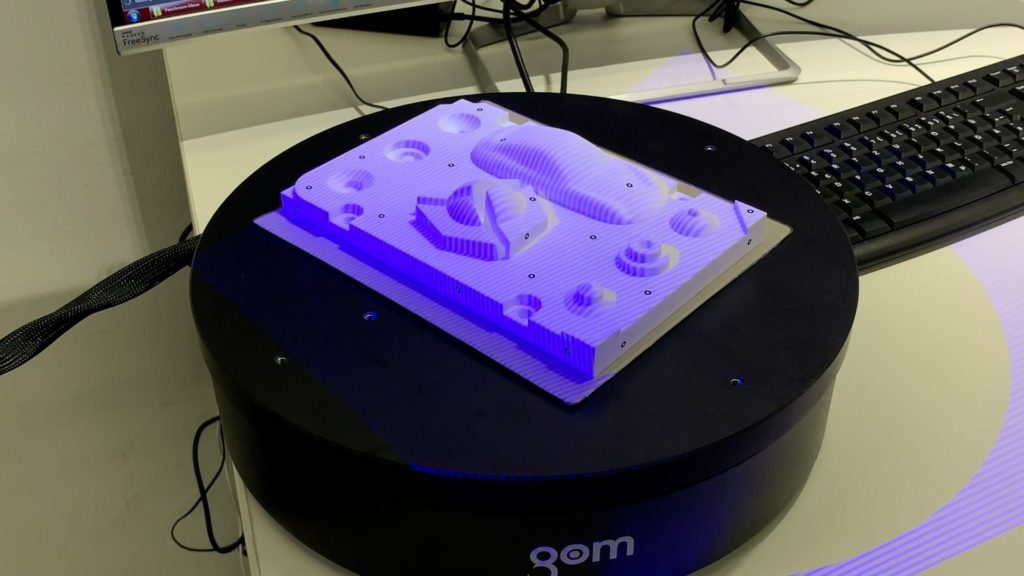

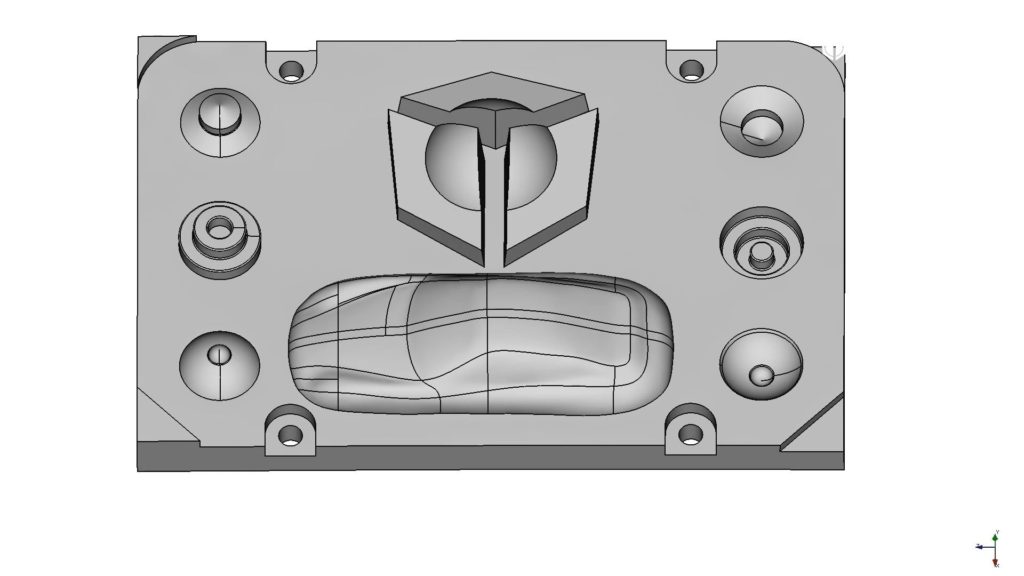

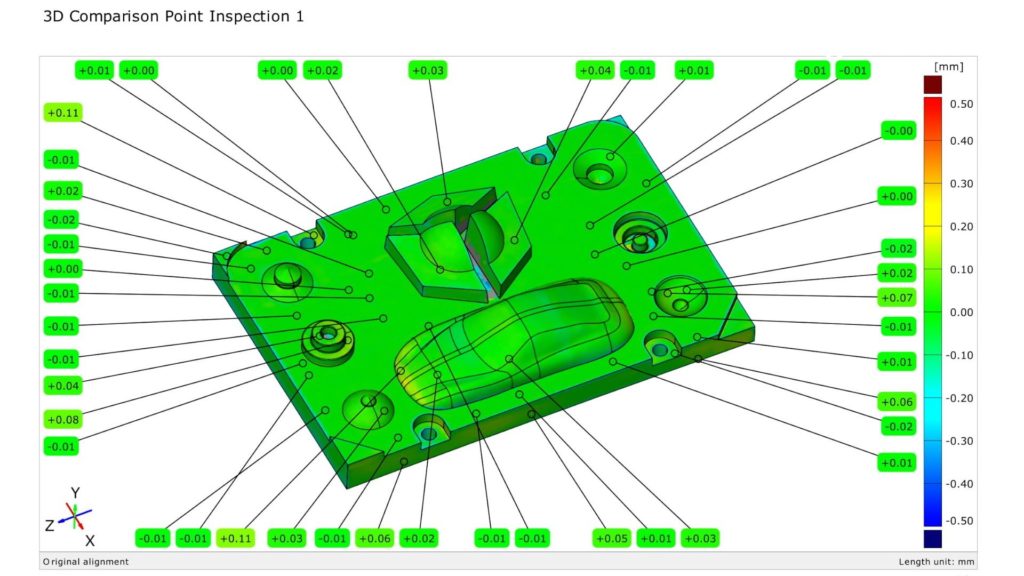

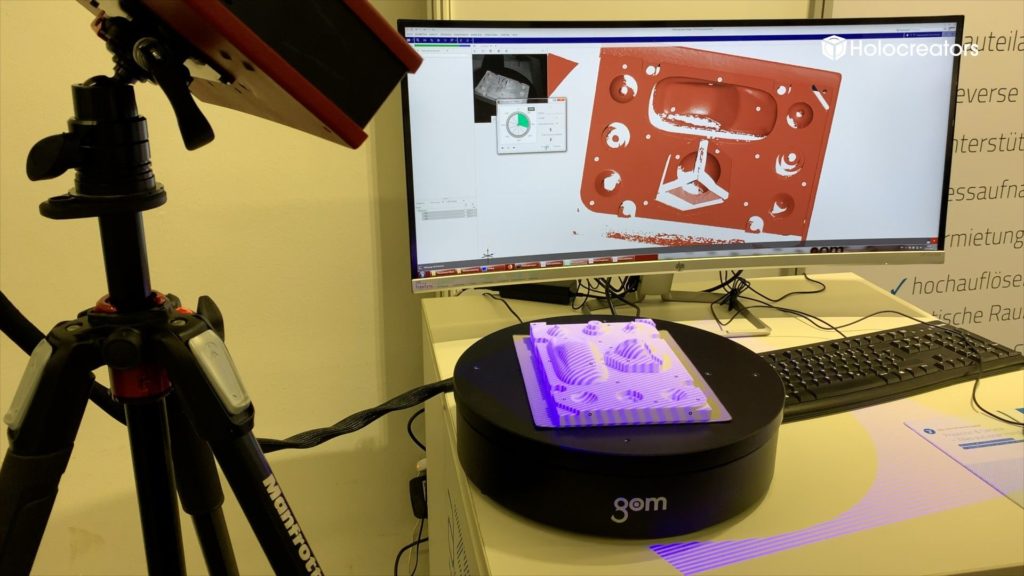

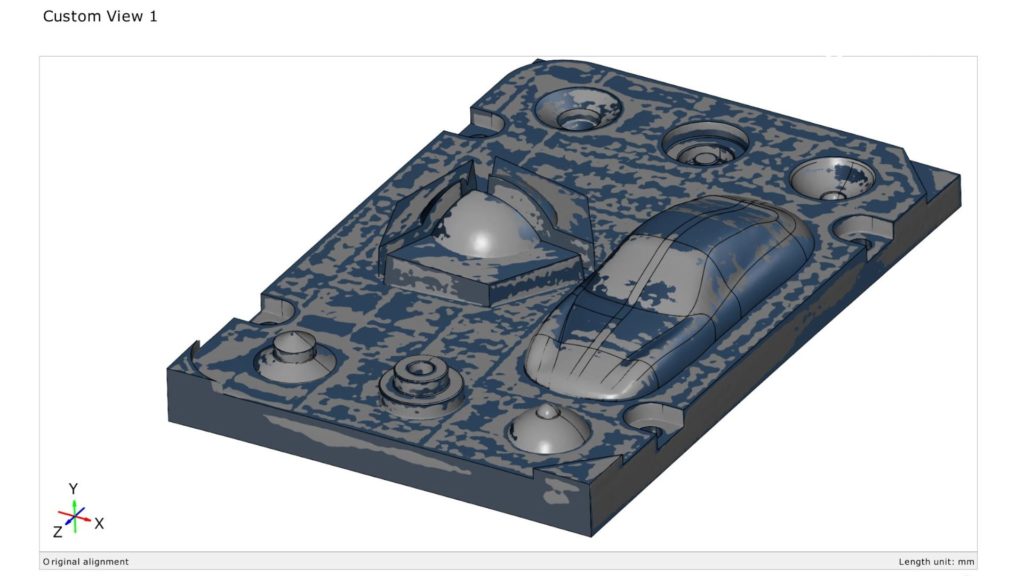

The reverse engineering process is the approximation of measured data (3D scan) by a CAD model. This means that we approach the 3D scan as close as possible by solid modeling. We use all CAD modeling techniques at our disposal to create a closed-and thus watertight-solid model.

In reverse engineering to solid modelling, simply geometries are reconstructed manually and NURBs surfaces are molded from the 3D Scan. A Hybrid model combining both geometry variants is also possible. The resulting solid model can be edited only to a very limited extent. Simple geometries like holes and threads can be modified, but the NURBs surfaces cannot be edited.

We make videos about 3D-scanning and reverse engineering. We will happily inform you when a new video goes online.